Adhesive Peel Tester tv shopping|peel testing techniques : import ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to as the “T-Peel” test because the sample looks like the letter “T” when loaded . webTeste Lucky Durian de Habanero 📈 Avaliação do jogo ️ A lista completa de casinos e dos seus bônus em setembro 2023 ️

{plog:ftitle_list}

Moviecom Macapá Shopping. Rua Leopoldo Machado, 2334 - Central. Ver no mapa.

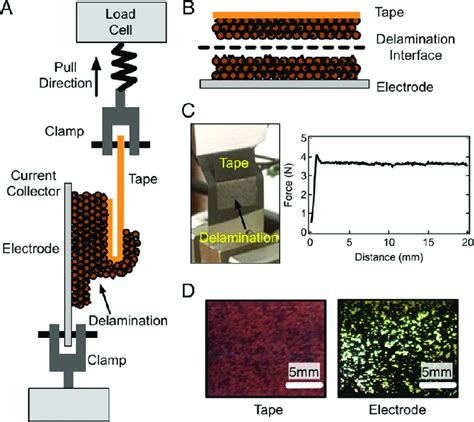

A peel adhesion tester is a specialized instrument designed to measure the adhesive strength of materials, including tapes, labels, films, and other packaging components. It simulates real-world scenarios by applying a .Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).How to Perform an Adhesive Strength T-Peel Test – ASTM D1876. There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, .

ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to as the “T-Peel” test because the sample looks like the letter “T” when loaded .

what is peel testing

Peel strength testing is often used to characterize the bonding strength of tape, adhesives, and flexible substrates, such as rubber, films, biomaterials, consumables, medical packaging and .The Peel Strength Tester from Presto is a quality testing instrument that will help you easily measure the adhesive strength of materials like packaging tapes. Widely used in the .Solutions. Peeling Resistance Tester. The S-PRT-2500 is used to perform the peel strength test. More specifically, it tests the bond between the adhesive/PE (or PP) top coat layers and the FBE layer. Advantages: Completely wireless .How to Perform a Peel or Strip Test on Adhesively-Bonded Materials. Written by Charlie Pryor. ASTM D903 is a common tensile test used to evaluate the peel or stripping characteristics of adhesively bonded materials used in a wide .

Elevate adhesive and peel testing with the Expert 7601 System. Redefine material analysis through advanced adhesion and peel testing. Learn more now.To perform a test to ASTM D903, the adhesive materials must be cut into specimens 1" x 12" long. The specimens are then peeled away from either a flexible or rigid substrate at a 180° angle at a separation rate of 152.4 mm/min, .

Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .Method F: 90° peel test to measure the adhesion properties of single-coated tapes; Specimen Conditioning. The rolls of tape to be tested must be conditioned per ASTM D4332 for at least 24 hours. The tape is applied to a 302 or 304 .

An adhesion tester measures the force required to detach a coating from a substrate. Often called a pull-off adhesion tester or peel tester, an adhesion tester applies a large amount of force to evaluate a coating's bond strength. When measuring peel force or adhesiveness, the nature of the substrate's surface plays a significant role. However . Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.

ISO 8510 -- Adhesives -- Peel test for aflexible-bonded-to-rigid test specimen assembly ; . CZY-8SA Lasting Adhesive Tester can be used to test the holding power of pressure-sensitive tapes, pressure-sensitive labels and protective films, etc. Request a .Testing Equipment for Peel Adhesion. A multi-functional peel tester is used to evaluate the peel force in different peel angles, rates, and temperatures (Figure 1). The peel tester is capable of evaluating independent parameters of peel rate from 15-300 cm/min, angle from 0° to 180°, and temperature (by a Weak adhesive bonds can lead to package failures, resulting in product damage, contamination, or loss. Factors like temperature variations, humidity, and handling during transportation can all impact adhesive strength, making it a critical parameter to measure. Peel Adhesion Tester: An Overview of the Machine. A peel adhesion tester is a .

ISO-8510-2 – adhesives – peel test for a flexible-bonded-to-rigid test specimen assembly – part 2: 180 ° peel SAE-J 1553 – cross peel test for automotive-type adhesives for fiber reinforced plastic (FRP) bonding

Complete your peel test system with our extensive range of accessories. With hundreds of options to choose from, you can easily find the perfect fixtures and sample preparation aids to complement your peel tester. We have everything you need to ensure a seamless and comprehensive testing experience. Shop some of our popular peel test accessories:ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to.Adhesive peel tester Product Introduction: Adhesive peel tester is an multifunctional tester, a ccurate and effective peel tester testing with 90 ° and 180 ° tape peeling, peel tester be with s ervo motor drive, precision ball screw drive, the computer set the test speed directly for adhesive force the physical property of strength resistance.

PSTC-3 Peel Adhesion of Double Coated Pressure-Sensitive Tapes at 180° Angle PSTC-4 Adhesion to Liner of Presure-Sensitive Tapes at 180° Angle 3. Terminology 3.1 Definitions—Terminology found in Terminology D 996 shall apply. 4. Summary of Test Method 4.1 Test Method A—Single-Coated Tapes, Peel Adhesion atPeel testing of adhesive and pressure sensitive tapes is used for quality assurance, and provides a means of assessing uniformity of the adhesion of a given type of tape. The assessment may be within a roll of tape, between rolls, or between production lots. Adhesive properties for tapes are measured using a standard test surface, a specified angle and test speed.Test angle is permanently set for 180° testing; 10 pound load cell is included with the machine; Capable of pulling up to 10 lbs (4.5 kg) Test samples as short as 1/2” to as long as 6” (12-150 mm) Designed to accept standard 2” x 6” peel .A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as .

High Speed Peel Strength Tester test the adhesive strength of adhesive material, 抗剥落性能, 可以做 180, 90 剥离度测试. 86-769-83078748 . 86-13751328225 [email protected] . 日本語 /ja/shop/lr-f019-high-speed-peel-strength-tester/

ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing standards such as ASTM D1781, ASTM D3330, ASTM D3167 and can also be customized based on your test application. Below we will explore the types of peel tests .

The Presto Peel Seal Bond and Adhesion Tester Digital cum Computerized Model is an advanced and reliable testing instrument designed for evaluating the peel adhesive strength of various test specimens. It is manufactured under test standard ASTM D 903, ASTM D3330 , ASTM F88 and ASTM F904.The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument. You can confidently report results knowing that the system has been engineered to meet all accuracy requirements specified in major standards organizations including .The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.

manual compression test quizlet

manual compression test stand

ASTM D1876 measures the comparative peel properties of adhesive bonds between flexible adherends by using a T-peel test. The test is referred to as a “T-peel” due to the shape the two flexible adherends form as they are pulled apart. Average peel strength for each specimen type and average, minimum, and maximum peeling loads for each individual specimen are the .ASTM D903 | Adhesives | Peel Testing. ASTM D903 is a common test performed for determining the strength of adhesive bonds. In the following procedures, a piece of tape or adhesive is bonded to a standard material and peeled backwards at a 180 degree angle. The main calculation determined through this ASTM standard is average peel or stripping .

This test is optimized for tapes with flexible backings, or tapes that are adhered to a similar flexible substrate. Unlike the 180 degree peel test and 90 degree peel test, the T-peel or trouser method is the easiest test to set up and conduct. These types of tests are often done on transfer tapes or at converting companies that may use tape to .

90-Degree Peel Test: The 90 Degree Peel Test is designed to assess the peel strength of adhesives used on rigid or semi-rigid materials. In this test, the adhesive material is peeled away from the substrate at a 90-degree angle, which better simulates the stresses encountered in real-world applications where perpendicular forces are involved.Configure your peel testing systems from a wide range of test frames, force sensors, grips, and accessories. See the list of items below for details. See the list of items below for details. Shown at left: F305-IMT test frame with an FS05-20 force sensor and G1008 film and paper grips .

ISO 11343 is a standardized Wedge Peel Impact test method used to measure the resistance of high-strength structural adhesives to cleavage fracture at various speeds and user-defined temperatures. The impact test consists of a wedge with a defined shape and mass, being driven at a defined velocity into the adhesive bond securing two metallic .

peel testing techniques

peel testing system

web10 de jan. de 2024 · O preço do morango declinou (-11,11%) no entreposto da Ceasa-CE em Tianguá, de acordo com o comparativo realizado no período de 5 a 9 de janeiro de .

Adhesive Peel Tester tv shopping|peel testing techniques